The art of stained glass is on the verge of extinction due to high energy costs, expensive raw materials and lack of skilled labour.

Abdel Rahman, who works in stained glass, said: “I can expect to earn LE200 a day and competition from Chinese products in the Egyptian market is not helping.”

“The raw materials such as sand are available on our doorstep, in Ras Sidr,” he told the Egyptian Mail, the weekly edition of The Egypitan Gazette.

However, the Chinese buy materials cheaply and export their products to Egyptian to sell at an inflated price. Egyptian stained glass just can’t compete, Abdel Rahman said.

“The industry is booming in China and they export their products worldwide and expand their factories, while in Egypt this industry is declining because of red tape and unstable prices of raw materials and gas, due to the floating pound, the absence of skilled labour and lack of government support, he explained.

The result was a severe blow to this traditional craft. Ten factories and workshops closed because their expenses had risen fourfold.

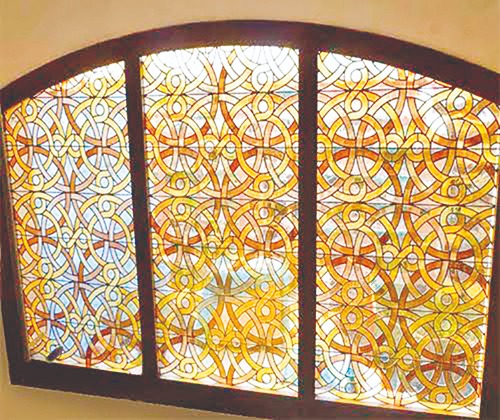

Stained glass is a sophisticated craft whose practitioners are doing their best to keep it going despite the challenges.

As for making a stained glass product, let Abdel Rahman explain.

“I use glass which is not originally coloured, then I colour it by mixing it with metal oxides in its melted state in a crucible or pot.

“This makes glass sheets that are coloured all the way through. This is known as “pot metal” glass.

“Another way is to mix potash and sand to 400 C and the add various metallic oxide powders to create different colours. I flattened the glass into sheets while it is still pliable.

“I cut the plates into small pieces according to the design and I paste this broken glass with glue inside a wooden or iron frame in the shape of, say, a bedside lamp, a lampshades, or window for a door – according to what the customer wants,”

“For coloured ceilings, I need glass 12 millimetres thick, and for doors and windows, 3 millimetres,” Abdel Rahman said.

Stained glass is used in places of worship and palaces.

Architect Hatem Fawzy said the price of lead for fixing and interlocking glass rose from LE30 per kilo to LE750. Welding tape is imported, so, after customs duty and VAT, it costs anything up to LE200.

Fawzy does not use Chinese materials as a substitute for the American because his customers appreciate high-quality materials.

“I’ve been in the busines 35 years and I’ll buy proper American glass at LE1800 per square metre. The colours are LE2500 for an ampoule.

“Arab and European customers can afford my work, but Egyptians have been feeling the pinch, which led to the closure of many workshops.

“I’ve lost about 30 per cent of my Egyptian custom,” he said.

Bahaa Afifi, who owns a stained glass workshop in Khan el-Khalili, blames the Chinese for loss of trade.

Afifi relies on women from poor families in el-Gamaliya district to make this glass at home to supplement the family income.

Discussion about this post